Dongguan Jinyu Automation Equipment Co., Ltd. was established in 2000. It was located in Dalingshan Town in early days. It moved to Chashan town on September 1, 2021, The factory covers an area of 4,000 square meters. Its a professional manufacturer of Silicone Machine, Pvc Machine, KPU shoe machines. As a high-tech enterprise integrating R&D.design.production.sales and after-sales service. And has a number of patents, well received by domestic and foreign customers unanimously praised, as an enterprise producing automation equipment, we will work with you to develop together.

►In 2000, founded pvc(plastic dropping) trademark equipment.

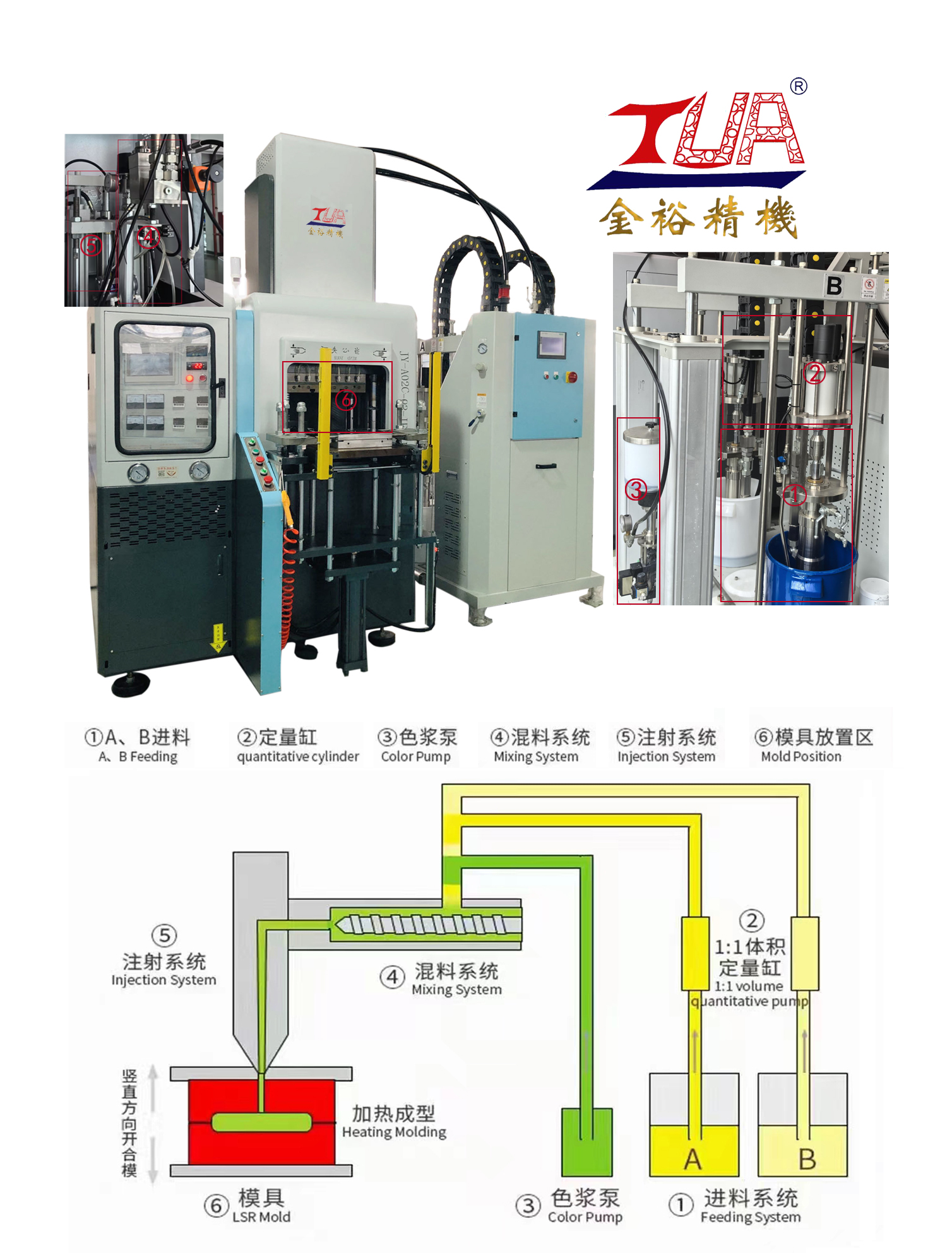

►In 2002, developed silica gal(silicone) trademark forming machine.

►In 2004, researched and developed Hydraulic Machine 30T, 50T, 63T, 100T.

►In 2006, researched and developed full automatic dispensing(dropping) equipment

►In 2008,researched and developed KPU shoes material making machine.

►In 2010,researched and developed Full automatic production line.

►In 2017,developed automatic(silicone and PVC) production line,intelligent robotic arm.

►In 2018, developed silicone in-mold transfer trademark.

►In 2019, R&D smart oven.

►In 2020, research and development of visual Dispensing Machine.

►In 2021, built a new factory three times larger than before.

►In 2022, R&D universal mold base.