Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

86-0769-85624738

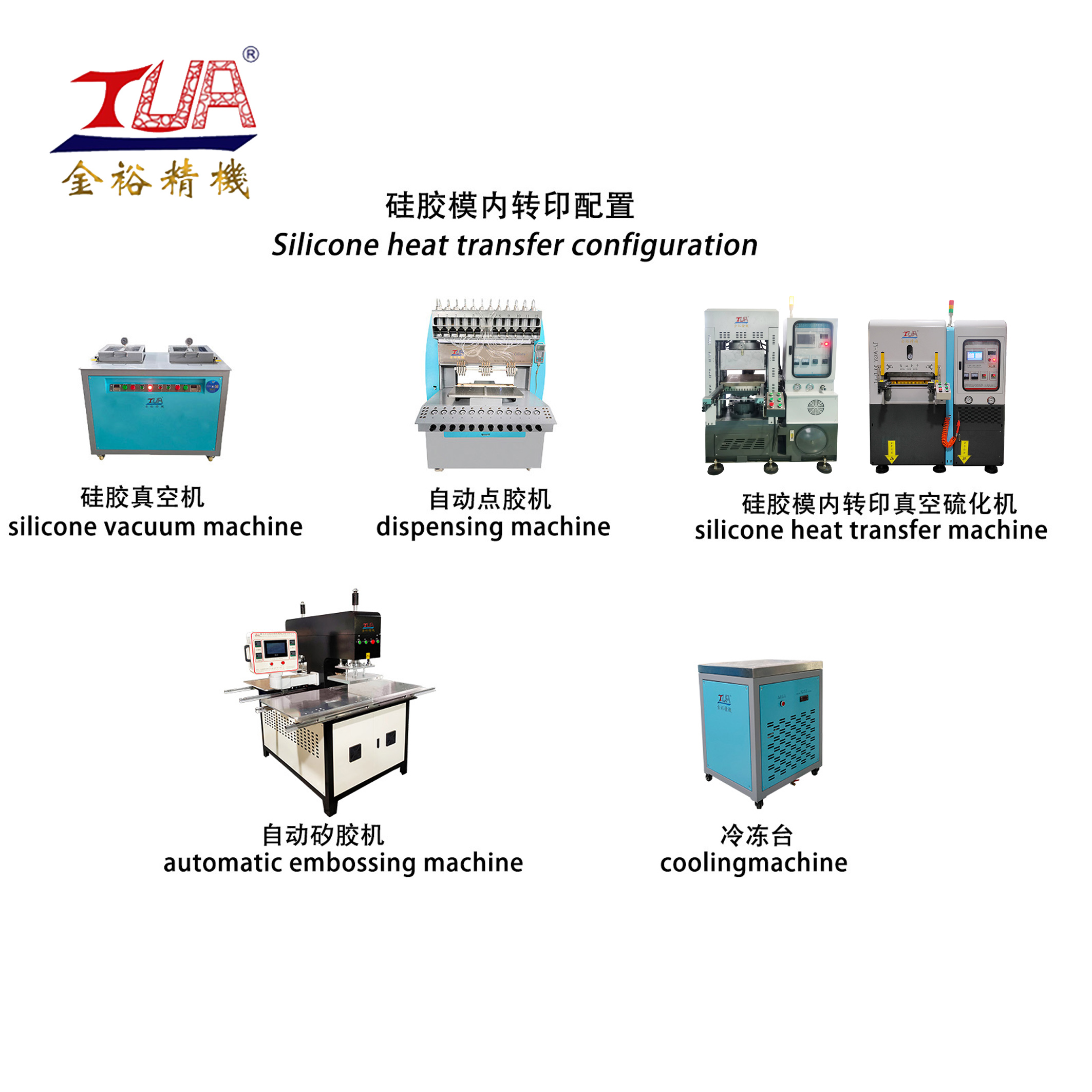

Multi-color integrated molding technology is currently a commonly used process technology for silicone product manufacturers, and the product process technology includes the current glue-drop processing method and roller printing and watermark or ink printing methods, and the glue-drop processing produces more. High-end three-dimensional effect, Dongguan Jinyu Machinery Equipment Co., Ltd. is specialized in the R&D, assembly and sales of silicone products and equipment. The machine equipment can not only be flat printed, but also can be concave-convex obliquely printed with edges and corners, rounded corners, etc., so what do you want from this method? ?

Dongguan Jinyu machine, China Silicone Heat Transfer Label Machine,Label For Embossing,Silicone Thermal Label Machine

It is suitable for silicone jewelry, decorative gifts, especially clothing and footwear trademarks, embossed printing, etc. For the IMD process technology on the surface of silicone, it still breaks through the single-color pad printing technology, which can perform multi-color integral molding on the surface of silicone products, and can be used on the surface of silicone products. The effect can be achieved when the structure is relatively complex, such as concave-convex structure, arc structure, and groove structure, etc. Its surface stamping pattern has the same effect as silk screen printing, and it can also achieve the advantages of wear resistance, scratch resistance, heat resistance and liquid resistance.

China Silicone Logo Making Machine supplier, offer high-quality Silicone Labels Making Equipment, Silicone Bracelet Maker Equipment, Silicone Wristband Making Machine, Silicone USB Case Making Equipment for you to choose. Also PVC Dispensing Machine,Silicone Dispensing Machine,Automatic Dispensing Machine

Previous: What is Dispensing Machine For PVC?

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.