Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

86-0769-85624738

How to improve the curing speed of silicone products?

For the manufacturing industry, the efficiency and quality of factory processing is the profit of the product. The recognition and support of the customer is the brand's reputation. Therefore, for the processing industry, the improvement and quality of the production capacity is crucial, in the silicone products industry. Product efficiency and quality are examples, so it is most important to improve efficiency and effectiveness. When it comes to this, it depends on the processing technology and methods of each industry.

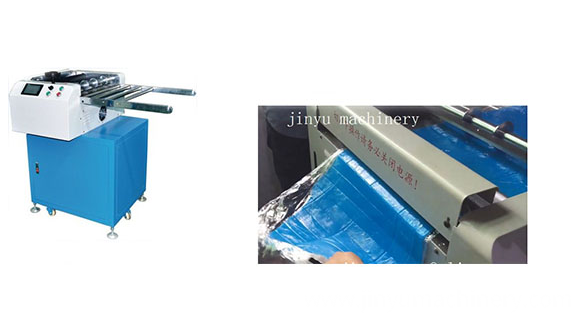

First of all, we need our machines from Dongguan jinyu Automation Equipment Co., Ltd. Our machines are recognized by our customers and everyone has confidence in our machines.

Single head vulcanizing machine

1. Adding appropriate release agent during raw material mixing can quickly release the mold, which can save some pick-up time.

silicone Rubber mixing machine

4, change the way of placing the material, the method of placing the material will also affect the demolding time of the product, and the long strip shape material can be appropriately replaced into a sheet shape, allowing it to spread the cavity faster.

6, the mold work up and down, open a few discharge troughs to allow the product to keep the remaining material discharge.

Dongguan jinyu Automation Equipment Co., Ltd.

We supply all the machines, molds & materials, support and etc, prepare everything you need to start the production!

we have cnc machine, and PVC Machines, Silicone Machines, kpu shoes upper machines,articulated robot.

YouTube:https://www.youtube.com/c/jinyumachine

website:jinyumachine.en.alibaba.com

whatsapp/WeChat/Line/Skype:+8613829130058

Facebook:nealjy

contact:Neal

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.