Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

86-0769-85624738

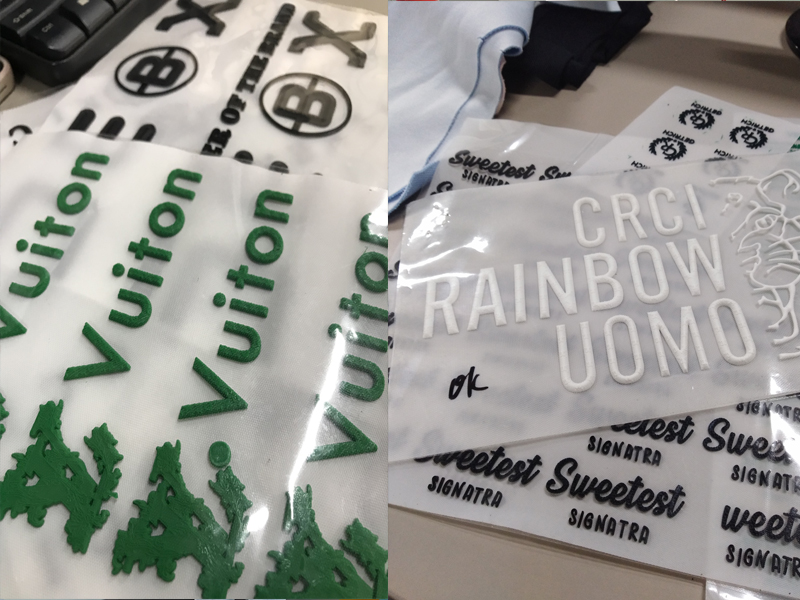

The method of thermal transfer printing silicone products of the present invention has simple operation steps, is easy to operate and implement, and can effectively control the quality of silicone products. The clothing products produced by adopting the process steps and parameters of the present invention are more closely combined with the silicone, thereby improving the product quality in all aspects and having a better appearance. The Dow Corning 3631 liquid silicone rubber used in the present invention has good elongation, low odor, good anti-slip effect, no solvent, and little pollution.

Jinyu Machinery provide the whole set of machines to make silicone heat transfer label, they are silicone mixing machine, Silicone Vacuum Machine, Silicone Dispensing Machine, silicone heat transfer machine, silicone Embossing Machine.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.